September 22, 2023

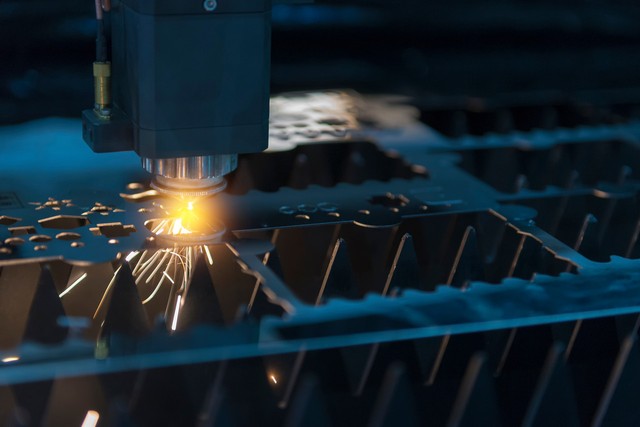

Laser cutting is a technology that uses laser beams to process materials laserpecker 2 pro. The following are some basic knowledge of laser cutting:

1. Characteristics of a laser: a laser is a high-intensity laser cutter, monochromatic, coherent beam. Its characteristics include:

-High intensity: the laser beam has a high energy density, which enables it to process materials laserpecker 1;

- monochromatic: laser beams are usually of a single wavelength with a narrow spectral width;

-Coherence: The light waves of the laser beam are coherent and have a constant phase relationship.

2. Laser cutting materials: laser cutting for a variety of materials, mainly including metal and non-metallic materials. Common applications include metallic materials such as steel, stainless steel, aluminum and copper, as well as nonmetallic materials such as plastics, wood, fiberglass and ceramics.

3. Types of laser cutting machines: According to different laser sources, laser cutting machines can be divided into CO2 laser cutting machines, fiber laser cutting machines, solid-state laser cutting machines and so on. Different types of laser cutting machine tools are suitable for different materials and application requirements.

Four. Cutting principle: the principle of laser cutting is to use the laser beam to heat the material, so that the local melting or evaporation of the material, and then through gas jet will melt the material dispersed, thus achieving the goal of cutting. The laser energy density and focusing ability have important influence on the cutting effect.

5. Cutting parameters: The quality and efficiency of laser cutting are affected by many parameters, including laser power, scanning speed, focus position, gas injection pressure and nozzle form. Reasonable adjustment of these parameters can obtain ideal cutting effect.

6. Cutting applications: laser cutting is widely used in metal processing, automotive manufacturing, electronic components, aerospace and other industries. It can realize high precision and high speed cutting of workpiece with different shape and size.

It should be noted that laser cutting is a processing method with high technical requirements, and operators need to have relevant safety awareness and professional knowledge to ensure safe operation and good cutting effect.

Posted by: stonerrr at

04:26 AM

| No Comments

| Add Comment

Post contains 398 words, total size 4 kb.

32 queries taking 0.0309 seconds, 66 records returned.

Powered by Minx 1.1.6c-pink.